Funded under:

Total cost:

399.989 €

Project duration:

23 months

Coordinator:

Foundation for Research and Technology- Hellas (FORTH)

Participants:

Democritus University of Thrace (DUTh)

Hellenic Mediterranean University (HMU)

CHALLENGE

The European Commission presented the “Green Deal” in December 2019 as “A roadmap for making the EU’s economy sustainable by turning climate and environmental challenges into opportunities across all policy areas and creating the transition just and inclusive for all”. In particular, it sets out how to make Europe the first climate-neutral continent by 2050 supporting the energy and mobility transition. With an increased number of new battery-powered car models on the market in order to meet the CO2 targets, this mobility transition seems easier than ever. Batteries today have a high efficiency reaching sufficiently high energy storage capacities to support renewable electricity production and clean transportation. Nevertheless, more research has to be done for batteries to reach the full potential of ultrahigh performance including new sustainable electrodes based on minimum or no use of critical raw materials, eco-efficient synthesis of electrodes and implementation of battery cells at low cost, consistent power over longer duration. Sustainability is specified starting from secure raw materials, environmentally – friendly manufacturing and standardization of energy storage cells for large-scale energy storage and electric vehicles in a circular economy context.

Energy storage market is growing fast and there is a continuous need for cheaper, lighter and thinner systems. Although Li-ion batteries (LiBs) present the most advanced storage technology so far, they still need further improvement in order to meet the high energy density goal of more than 300 Wh/kg that would be highly appreciated in the automotive industry.

OVERALL CONCEPT

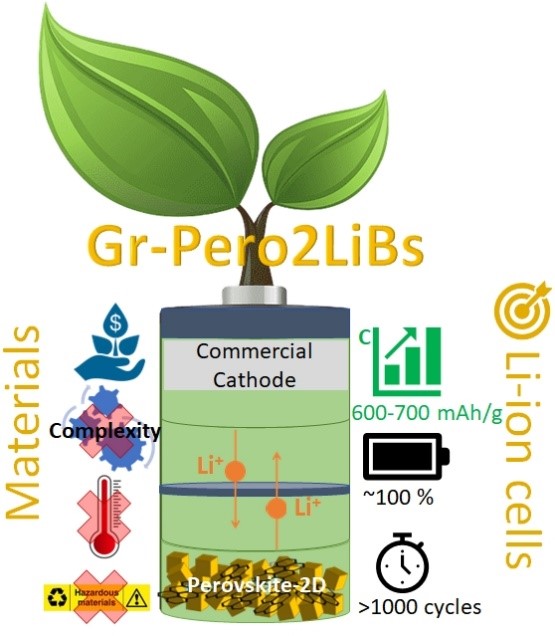

The overall concept of this project is the implementation of a one-step, cost-efficient and low-temperature process that enables the production of conjugated systems as electrode materials taking advantage of the synergetic effects among the perovskites and 2D materials across the interfacial connections (FORTH). Apart from the electrodes, aqueous electrolytes such as LiCl, LiNO3, LiSO4 and Lithium bis(trifluormethanesulfonyl (LiTFSI) will be initially investigated to find the dominant performing combination of electrode-electrolyte, minimizing the detrimental reactions associated with the electrode-electrolyte interface (HMU). Then, the optimum conjugated anode material and the optimum electrolyte provided by the electrochemical screening will be utilized from DUTh to manufacture a slurry-based anode electrode that will be implemented and evaluated in half-coin cell configuration and full pouch cells with commercial cathodes and separators.

The quantifiable objectives of Gr-Pero2LiBs are:

1) Development of a low cost, simple growth technology of anodes.

2) Working green prototype anodes with capacity ranging 600-700 mAh/g, coulombic efficiency close to 100 % and long-term stability (> 1000 cycles).

3) Validation of working-prototype anodes through relevant environments and measurements in half coin and full pouch cells.

OBJECTIVES

O1. Το find the optimum cost effective, sustainable, and easy processable Pb-free perovskite for Li-ion cell.

O2. To find the optimum cost effective, sustainable, and easy processable conjugated material (Pb-free perovskite-2D material) for Li-ion cell.

O3. To optimize the electrode-electrolyte combination.

O4. To develop an anode including the optimum Pb-free-2D conjugated energy storage material that can deliver a real specific capacity of more than 2 mAh/cm2 and a long cycling lifetime.